Why Leak-Proof Fittings Are Essential for Industrial Automation Systems

- Industrial Service Components Inc.

- Jun 19, 2025

- 4 min read

In today’s fast-paced world of industrial automation, reliability isn’t a luxury, it’s a necessity. Every valve, sensor, actuator, and fitting must work seamlessly to ensure your systems operate at peak performance. Yet one of the most overlooked causes of downtime and costly maintenance is the smallest component in the system: the instrumentation fitting.

Leaks caused by poor-quality fittings or improper installation can lead to production halts, energy loss, equipment damage, and even serious safety hazards. In fact, in highly automated systems, even a minor pressure leak can cascade into a full-blown shutdown. For manufacturers looking to stay competitive, leak-proof fittings are not optional ,they are mission-critical.

The Role of Fittings in Automated Systems

Instrumentation fittings act as the connective tissue in industrial automation systems. These small but powerful components ensure secure, leak-free connections between tubing, valves, sensors, regulators, and pneumatic or hydraulic systems. In a typical automation environment, fittings help manage:

Fluid and gas transfer

Pressure regulation

Data acquisition (via sensor connections)

System isolation and actuation

When fittings fail or degrade over time, it can affect not just the flow of media but the accuracy of your control systems, potentially throwing off measurements, creating instability in pressure, or triggering false system alerts.

The Hidden Costs of a Leak

Leaks in industrial automation aren’t just annoying, they’re expensive. The average factory loses 20% to 30% of its compressed air due to leaks. In critical systems like food processing, pharmaceuticals, or semiconductor manufacturing, a single fitting failure can result in:

Production downtime

Contaminated product batches

Costly cleanups

Quality control failures

Regulatory non-compliance

Chemical Processing: $130,000/year

Food & Beverage: $85,000/year

Compressed Air Systems: $70,000/year

Pharmaceutical: $95,000/year

Where Leaks Happen & Why

Most leaks occur at connection points where fittings meet tubing or components. Here are the top causes:

Improper torque during installation

Tube end damage (burrs, scratches)

Mismatched or low-grade materials

Vibration fatigue and thermal cycling

Poor seal design or lack of a backup inspection system

What Makes a Fitting Truly Leak-Proof

To ensure leak-free performance in industrial automation, high-quality fittings must be engineered to overcome the above failure modes. Superlok fittings, for example, offer:

Dual Ferrule Technology: Ensures uniform grip around the tubing, reducing leak paths

Zero-Gap Inspection Ring: Patented feature that visually confirms proper installation

Tapered Threads and Precision Machining: Creates tighter seals under pressure

Vibration Resistance: Ideal for high-cycle automated environments

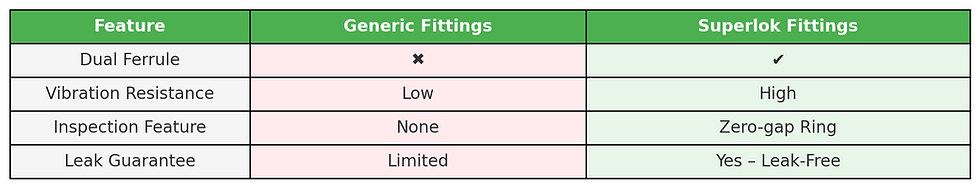

Figure 4: Feature comparison between generic fittings and Superlok leak-proof fittings.

Use Cases in High-Stakes Industries

Leak-proof fittings are especially critical in the following sectors:

Semiconductor Manufacturing: Ultra-clean environments require air-tight seals

Biotech & Pharma: Prevent cross-contamination and ensure compliance

Food & Beverage Processing: Leaks can lead to sanitation issues

Chemical Automation: Prevent hazardous material exposure

Packaging & Robotics: Maintain consistent pneumatic control

Why ISC Is the Go-To for Automation Fittings

At Industrial Service Components Inc., we don’t just sell fittings, we solve reliability problems. Our team works with engineers, OEMs, and plant managers across the Pacific Northwest to match the right fitting to your exact application. Here’s what sets us apart:

Authorized Superlok Distributor

Extensive Inventory for fast fulfillment

Bulk Ordering & OEM Support

Engineering Sales Team to consult on system compatibility

Strategically Located in Vancouver, WA with reach into Oregon, Idaho, and beyond

Need leak-proof fittings for industrial automation that won’t fail your automation system? Contact ISC today for bulk pricing, technical support, and fast turnaround times.📞

360-597-3061 | ✉️ sales@iscnow.us | Contact Us Form

In the world of industrial automation, precision and performance are everything. And nothing compromises those faster than a leak. Don’t let something as small as a fitting create large-scale consequences. By investing in high-quality, leak-proof instrumentation fittings from Industrial Service Components Inc., you’re not just buying parts, you’re protecting your productivity, your people, and your bottom line.

Frequently Asked Questions:

Q: What are leak-proof fittings used for in automation systems?

A: Leak-proof fittings ensure sealed connections in fluid and gas control systems within automated manufacturing environments.

Q: Why is leak prevention important in industrial systems?

A: Even minor leaks can cause pressure loss, signal failure, safety hazards, and unplanned downtime in automation processes.

Q: Do Superlok fittings work in high-vibration or high-pressure systems?

A: Yes, Superlok fittings are engineered for high-performance use in demanding applications like chemical processing, semiconductors, and manufacturing automation.

Q: Where can I buy Superlok fittings in the Pacific Northwest?

A: Industrial Service Components Inc. is an authorized Superlok distributor based in Vancouver, WA, serving the entire Pacific Northwest.

© 2025 Industrial Service Components Inc. All rights reserved.

Industrial Service Components Inc. is an authorized distributor of Superlok fittings, proudly serving industrial customers across Washington, Oregon, Idaho, California, and the greater Pacific Northwest. This content is intended for informational and educational purposes only. For custom quotes or technical support, please contact us at sales@iscnow.us or call 360-597-3061.

Comments